Exterior Wall Cladding Aluminum Sheets With Perforated Patterns For

Building Decoration

Gallery

Exterior Wall Cladding Aluminum Sheets With Perforated Patterns For

Building DecorationAluminium Panels with Perforated Patterns Customized to Wall

Covering or Ceiling Decoration

Key Words

Perforated metal sheet, perforated aluminum sheet, Wall aluminum

cladding, Aluminum Plate, Perforated aluminum panel, Aluminum

Panel, wall cladding, metal wall panel, Aluminum wall panel,

aluminium wall panel, exterior wall panels, Aluminum sheet, curtain

wall panel, Wall panel, metal wall cladding, Aluminum Wall cladding

panel, aluminum curtain wall panel, aluminum curtain wall cladding

panel, Metal panel, aluminum wall cladding, Aluminum composite

panel, wall cladding panel, Aluminum composite sheet, Aluminum

ceiling panel, Aluminum ceiling, aluminum cladding, Aluminum

cladding panel, aluminum facade panel, Ceiling panel, Ceiling tile,

Aluminum honeycomb composite panel, Aluminum honeycomb panel, Metal

cladding panel, Corrugated Aluminum Sheet, aluminum coil, aluminum

plate, building material, decoration material, construction

material, ACP, Aluminum composite material, ACM, aluminium

composite panel

What Is Wall Cladding?

At the most fundamental level, wall cladding is any material used

in the construction industry that’s installed on the exterior of a

building and serves as part of the building envelope. The wall

system provides numerous functions and advantages, from providing

thermal insulation and air and moisture resistance, to adding

design and aesthetic character to a building’s appearance and

structure.

Wall cladding finishes may vary from a material’s natural finish to

painted, treated, or physically altered to meet a specific design

intent. In recent years however, there’s been a huge shift towards

product and finish selection based on factors related to

sustainability, building performance, and the safety and wellbeing

of its occupants.

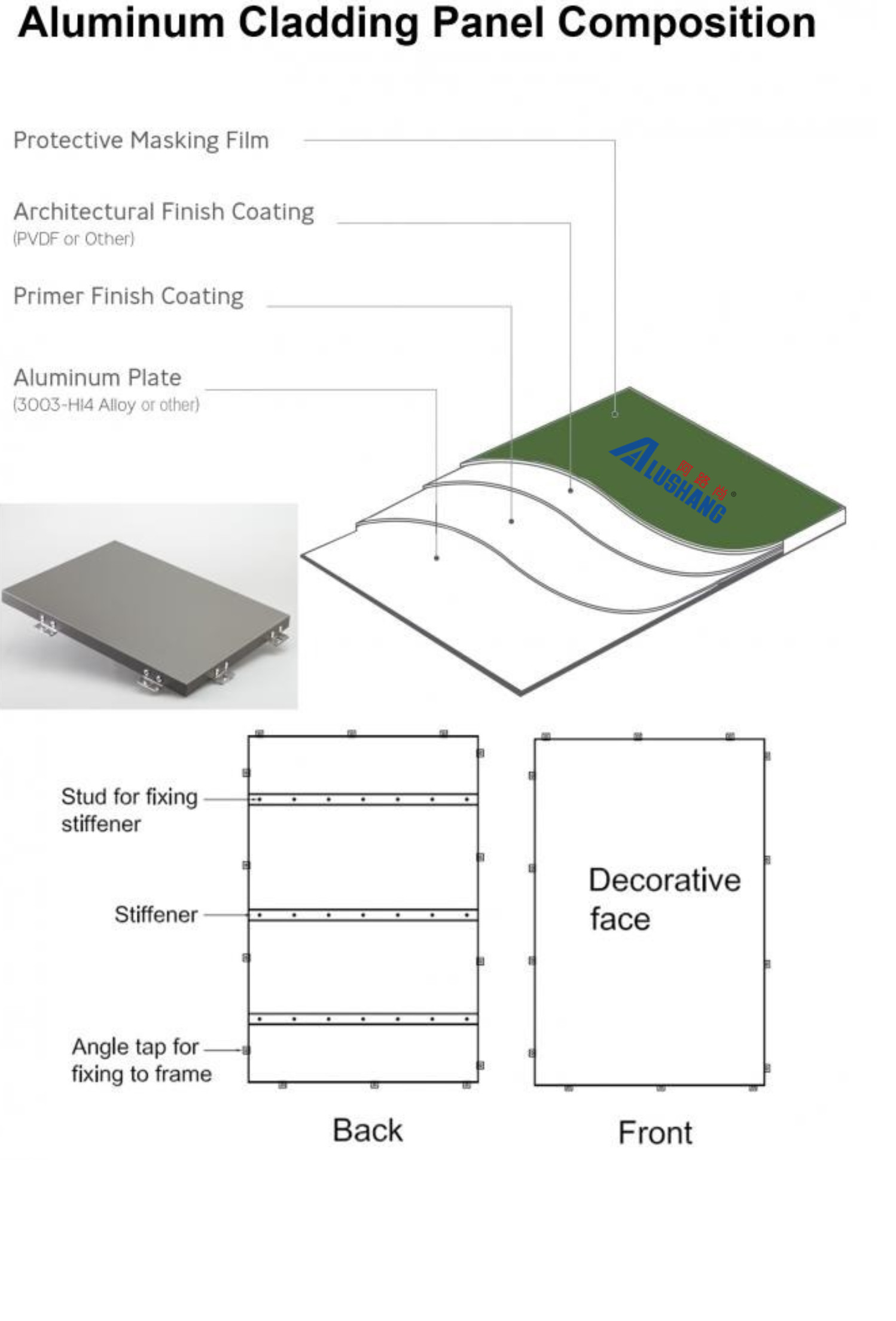

Descriptions of Aluminum Sheets

Aluminum Sheet is a very popular material applied in many fields,

especially commonly used for commercial building wall cladding and

decoration as well as ceiling and roof envelope. As a lightweight

material with excellent formabilities, aluminum sheets are

fabricated in many different designs and shapes to help the

architects with unique design ideas and concepts. With aluminum

sheets that customized to special designed aluminium panels for

wall cladding, facade envelope, column envelope, awning or eave or

canopy envelope and decoration, the modern builsing are designed to

be many special styles, giving unique landscapes for the cities.

The popular thiskness aluminum sheets applied for building

decorations is 0.5mm, 0.6mm, 0.7mm, 0.8mm, 1.0mm, 1.5mm, 2.0mm,

2.5mm, 3.0mm, 4.0mm, 5.0mm etc. You can use the aluminum sheets for

not only wall cladding and decorations but also roofs and ceilings

decoration.

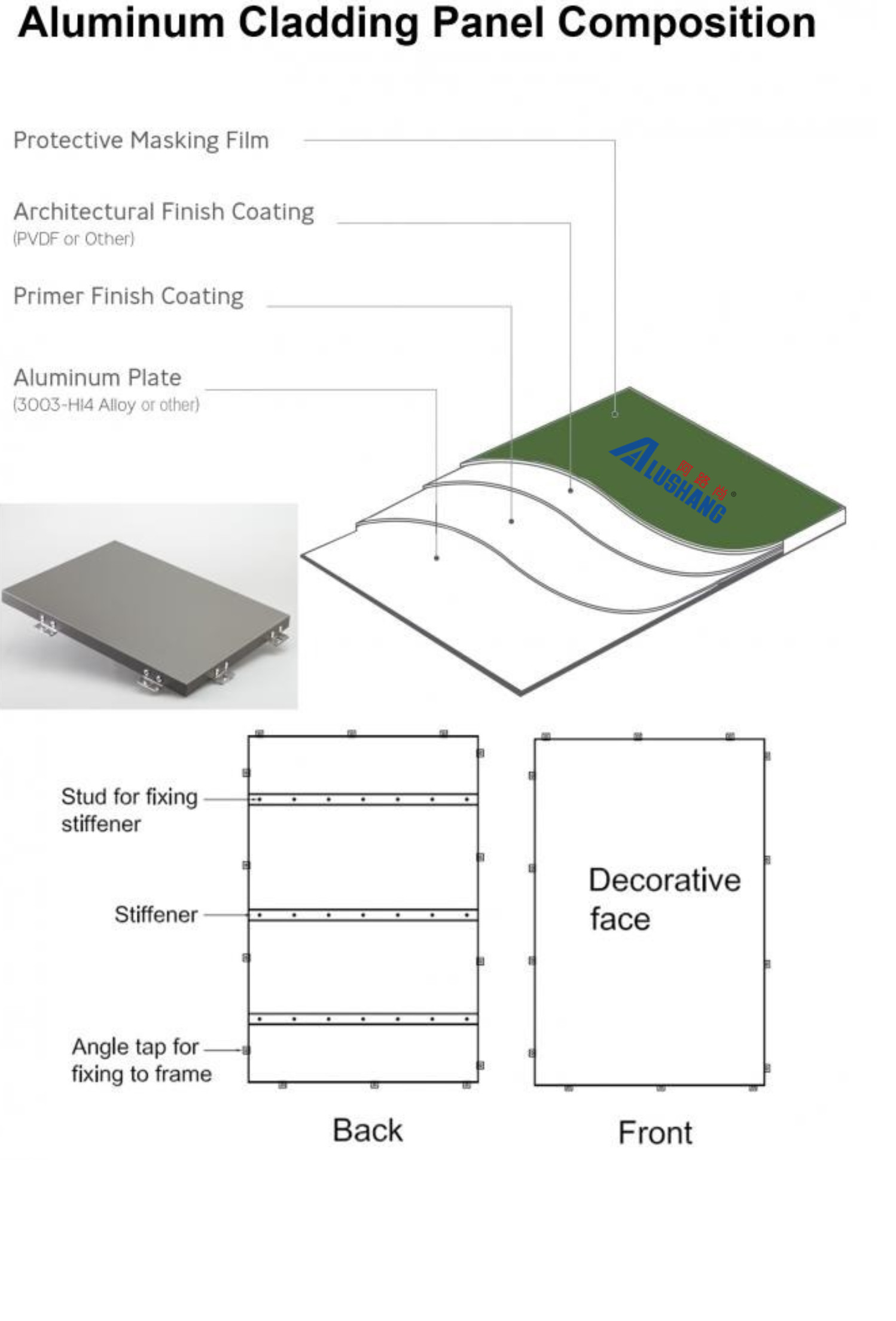

How to Install the Aluminium Wall Cladding?

Aluminum wall cladding system is also called as aluminum curtain

wall system which is an independent glazing system of a building,

it is extended by some castings that are welded with metal

structures for installing the cladding panels. On the modern

market, the most popular cladding materials are stone panels, glass

panels and metal panels or composite panels, while aluminum panels

are the most popular metal cladding materials for the curtain wall

glazing. The aluminum panels are prefabricated according to the

installation structures and dimensions as well as architecture

designs, the aluminium panels are fixed to the framing structures

by self-tapping bolts and the gaps among aluminum panels are sealed

by silicone sealants for a close glazing curtain wall system.

Why Use Aluminum Cladding?

Aluminum wall cladding is a material of choice in numerous

configurations including single skin sheet, thicker solid aluminum

plate, and aluminum composite material (ACM) consisting of two

aluminum skins bonded to a solid fire-retardant core. There are a

number of reasons why aluminum wall cladding is the preferred

choice.

Sustainability. Aluminum is a continuously recycled metal with almost 75% of all

the aluminum ever produced still in use today.

Versatility in function. Finished aluminum wall cladding can be formed into various shapes

and configurations, and with a natural light weight and high

strength to weight ratio, can be installed faster and more

economically than heavier wall cladding choices. This enables

architects to design buildings that meet their vision while taking

advantage of the functional benefits of the material.

When properly designed and installed, aluminum wall cladding, as

part of the exterior wall assembly, is an integral part of a

building’s weather resistance, preventing unwanted air and water

intrusion while providing specific energy performance.

It also contributes to the safety and welfare of a building’s

occupants as wall assemblies must comply with fire safety

requirements.

Finally, aluminum wall cladding can be finished with a wide range

of options from physical texturing, such as embossing or

roll-forming sheet, to anodizing, spray coating, and coil coating

sheet and plate. The type of finishing employed depends on the

needs of the application as well as the limitations of the wall

cladding product itself.

For pre-finished aluminum wall cladding, such as single skin sheet,

ACM aluminum composite material, and solid aluminum plate, coil

coated finishing is the typical application process of choice.

Architects specify coil coated finishes because of their color

consistency and durability. When utilizing AAMA 2605 compliant

paint coatings such as 70% resin kynar, the material can be backed

by industry standard finish warranties spanning 20 or 30 years from

installation.

In addition to industry standard solid colors to finishes that are

more metallic in appearance, coil coating opens up a plethora of

finishes, from solid color, metallic like colors, and specialty

finish options that mimic wood, natural metals, and even stone

finishes.

Shipping:

The aluminum veneer product is transported by sea freight. The

shipping costs are determined according to the order quantity and

destination. The shipping time differs depending on the selected

method and destination. Customers will be supplied with a tracking

number so that they can monitor the shipment status.

Thank you very much for viewing this page

Sincerely look forward to our cooperation!